New flexible 2D gas sensor soon to be protecting you from toxic ammonia

05 Dec, 2023

Your smartwatch could soon save you from more than missed meetings with a new miniaturised ammonia gas sensor in development. The sensor—made from 2D liquid metal and fabricated using a simple, cost-effective technique—could one day be integrated into wearable devices, monitoring your environment for harmful levels of toxins.

Ammonia is an invisible silent threat that can lead to chronic lung conditions and irreversible organ damage when a person is exposed to high levels. Generally, this exposure results from close proximity to high-production agricultural and industrial areas or faulty home appliances. According to industry estimates, 235 million metric tons of ammonia were produced globally in 2019, and that number is projected to rise to approximately 290 million metric tons by 2030.

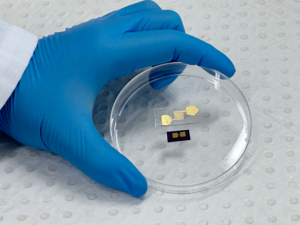

Researchers from TMOS, the ARC Centre of Excellence for Transformative Meta-Optical Systems, are working to address the dangers of undetected ammonia exposure by developing a gas sensor using atomically thin transparent two-dimensional (2D) tin dioxide film. The material has a thickness of only 2 nanometres which is 50000 times thinner than a paper. Reducing the thickness to only a few atoms substantially increase the flexibility of the material and makes it ideal for integration into wearable devices such as smartwatches and medical patches.

The tin oxide acts as an electric ‘nose.’ The presence of ammonia in the air changes the electrical resistance of the material. The higher the level of ammonia, the greater the resistance change. As a result, the sensor can differentiate between safe and dangerous levels of the toxin in the surrounding environment.

Current standard ammonia detection is mostly based on advanced approaches like gas chromatography. This is accurate for ammonia measurement, but its use is complicated and requires qualified staff, laborious sampling and preparation, and expensive laboratory equipment. The process is time-consuming and, due to the size of the equipment needed, not portable. In addition, the manufacturing of current ammonia detectors often involves expensive and complicated processes to prepare sensitive layers for sensor fabrication,

By contrast, the gas sensors developed by the TMOS researchers from the University of Melbourne and RMIT utilized a simple, low-cost liquid metal printing technique to deposit 2D tin dioxide that only requires a single synthesis step without using any toxic solvents, vacuum, and bulky/expensive instruments. Importantly, the fabrication method aligns well with existing silicon industry manufacturing processes, paving the way for easy fabrication adoption for mass production.

Despite its ultra-thin form factor, the 2D sensors are highly sensitive, due to their high surface area-to-volume ratio. The developed sensors demonstrate an unprecedented capability to detect ammonia at ultra-low concentrations (down to parts-per-billion) and outperform conventional sensors in terms of chemical sensitivity, selectivity, and stability showcasing impressive potential for long-term installation. The team demonstrated that engineering materials at the nanoscale can present enormous opportunities in emerging sensing applications. The researchers’ peer-reviewed article, “Instant-in-Air Liquid Metal Printed Ultrathin Tin Oxide for High-Performance Ammonia Sensors”, is published in Advanced Functional Materials.

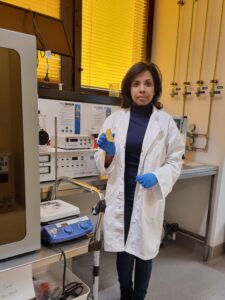

Lead corresponding author, McKenzie Fellow Dr Nitu Syed, says, “These novel nanosensors are safer and less tedious than existing techniques for monitoring toxic ammonia gas, and the sensor functions consistently and robustly after months of use. This innovation has far-reaching implications, from enhancing safety in industrial settings where ammonia is used, to enabling non-invasive medical diagnosis through breath analysis.”

Lead corresponding author, McKenzie Fellow Dr Nitu Syed, says, “These novel nanosensors are safer and less tedious than existing techniques for monitoring toxic ammonia gas, and the sensor functions consistently and robustly after months of use. This innovation has far-reaching implications, from enhancing safety in industrial settings where ammonia is used, to enabling non-invasive medical diagnosis through breath analysis.”

TMOS Chief Investigator Professor Kenneth Crozier says, “While several applications of the liquid metal-derived 2D oxides have been reported so far, their gas-sensing properties remain largely underexplored despite their cost-effectiveness, scalability, repeatability stability, and suitability for mass-production.”

TMOS Chief Investigator Professor Ann Roberts says “This is an exciting development that will underpin progress in the development of low-cost, wearable technologies enabling access to individuals working and living in potentially polluted environments. Ultimately, this can pave the way to improved air quality across the world”.

Co-corresponding author, Dr. Ylias Sabri, Senior Lecturer from RMIT, says, “As the world moves away from fossil fuels, green ammonia is predicted to play a central role in the energy transition. While ammonia is already used on vast scales, introducing it into the transportation sector will require the deployment of robust monitoring equipment to ensure safe operation, a task that must keep pace with the development of new fuel sources. This is one key use case for our device, and we’re keen to discuss with the industry ways to help it move forward.”

Co-corresponding author, Dr. Ylias Sabri, Senior Lecturer from RMIT, says, “As the world moves away from fossil fuels, green ammonia is predicted to play a central role in the energy transition. While ammonia is already used on vast scales, introducing it into the transportation sector will require the deployment of robust monitoring equipment to ensure safe operation, a task that must keep pace with the development of new fuel sources. This is one key use case for our device, and we’re keen to discuss with the industry ways to help it move forward.”

For more information about this research, please contact connect@tmos.org.au

Instant-in-Air Liquid Metal Printed Ultrathin Tin Oxide for High-Performance Ammonia Sensors

Advanced Functional Materials, 15th November 2023

Chung Kim Nguyen, Patrick D. Taylor, Ali Zavabeti, Hamidah Alluhaybi, Samira Almalki, Xiangyang Guo, Mehmood Irfan, Mohammad Al Kobaisi, Samuel J. Ippolito, Michelle J.S. Spencer, Sivacarendran Balendhran, Ann Roberts, Torben Daeneke, Kenneth B. Crozier, Ylias Sabri, Nitu Syed

Liquid metal-based printing techniques are emerging as an exemplary platform for harvesting non-layered 2D materials with a thickness down to a few nanometres, leading to an ultra-large surface-area-to-volume ratio that is ideal for sensing applications. In this work, the synthesis of 2D tin dioxide (SnO2) by exfoliating the surface oxide of molten tin is reported which highlights the enhanced sensing capability of the obtained materials to ammonia (NH3) gas is reported. It is demonstrated that amperometric gas sensors based on liquid metal-derived 2D SnO2 nanosheets can achieve excellent NH3 sensing performance at low temperature (150 °C) with and without UV light assistance. Detection over a wide range of NH3 concentrations (5–500 ppm) is observed, revealing a limit of detection at the parts per billion (ppb) level. The 2D SnO2 nanosheets also feature excellent cross-interference performance toward different organic and inorganic gas species, showcasing a high selectivity. Further, ab initio DFT calculations reveal the NH3 adsorption mechanism is dominated by chemisorption with a charge transfer into 2D SnO2 nanosheets. In addition, a proof of concept for prototype flexible ammonia sensors is demonstrated by depositing 2D SnO2 on a polyimide substrate, signifying the high potential of employing liquid metal printed SnO2 for realizing wearable gas sensors.